Industrial safety coatings

Guarantee the safety and reliability of the industrial tool

OliKrom is the specialist in smart coatings for industrial safety.

Our smart coatings are capable of changing color and/or luminescence on demand. They offer multiple possibilities to increase safety and detect hazards.

We make color talk to track the presence of an anomaly on an equipment for the protection of workers.

OliKrom works with many companies to develop innovative solutions to enhance safety: protection of tools, equipment and workers, detection and control of hazards, reporting of anomalies or incidents.

We use the richness offered by smart materials. The options for creating interactive devices (sensors, indicators, components, etc.) with their environment are limitless.

Custom coating deposited on equipment can become reactive to temperature, light (photochromes and luminescents), pressure, solvents or gases in order to monitor industrial risks: leaks, to detect abnormal heat, to monitor health-materials, etc.

This allows us to contribute to the resolution of numerous industrial hazards and workers protection needs, as in the case of our partnerships in the aeronautics industry with the Safran Turbomeca and Airbus groups.

A self-supporting safety coating

A very interesting property of smart coatings is their ability to modify their optical response autonomously, without any power supply. This allows us to intervene for the protection of workers and equipment in very restrictive environments, where any electrical source is totally or partially forbidden during certain phases of intervention.

No electricity needed, the color change in a smart coating (paint & ink) occurs only when the threshold is crossed. It is a thermodynamic process that acts as a passive solution. It's all in the initial programming of the product to calibrate the right trigger threshold and the reversible or irreversible nature of the color change.

Color change coatings are becoming alternative solutions to electronic sensors for equipment hazards monitoring. For example, the use of thermochromic coatings can replace thermocouples and/or thermometers: this is now a reality.

Visual detection

For some protection uses, the alert function sought is a visual detection. The process of color change is often preferred for its simplicity of interpretation and its understanding by everyone.

For example, an operator who observes the color change of a thermochromic ink or paint on the coated surface :

- of a motor to warn of an overheating condition or of an electrical element to identify a short circuit,

- a tank to visualize its filling level,

- an industrial pipe (or valves, ovens...) to control the appearance of a heat peak.

In this case, we will adjust the color change to the malfunction to follow. We will integrate the notions of duration of the event (time scale, number of ON/OFF cycles), choice of colors, implementation, improvement of the safety and health of workers...

Monitored detection

For certain health protection risks for workers, our teams develop solutions to create an interaction with an optical device (camera, video surveillance, drone, robots...).

Based on the targeted application, we adjust the wavelength, the selectivity and the reactivity of the coatings. This allows us to automate the detection, for example, an smart coating allowing a drone to detect the presence of a leak on an overhead pipe, an abnormal heat peak...

This wavelength selective work allows us to adapt the detection to the demand. We can accentuate the desired component according to the RGB color space. Other requests lead us to interact in the infrared or ultraviolet range to monitor health-products.

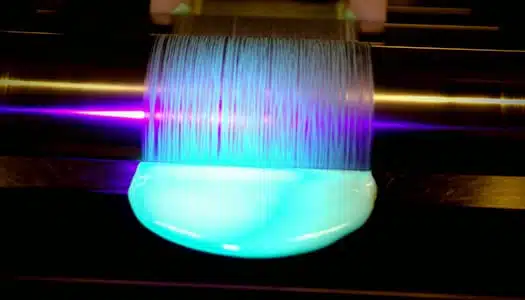

Amplified detection: making the invisible visible

For certain equipment, the objective is to detect the first signs of a malfunction.

In this context, our R&D services are developing a series of technical smart coatings, paints and inks, incorporating for instance fluorescent and/or phosphorescent components to monitor health-materials.

Some solutions are currently deployed for quality control of certain products during production and/or after return to the after-sales service (to visualize the conformity of a product). Other applications aim to detect the early signs of corrosion, the presence of residual water on a product to prevent the occurrence of safety risks...

Our teams have worked alongside the Safran Turbomeca Group to develop thermochromic coatings for mapping the temperatures of components integrated into complex environments, such as engines in operation subjected to intense heat and mechanical stress.

This development was supported by the FRIMATT program (Formulation of Innovative Coatings for Adapted Temperature Measurement on Turbomachinery) as part of the 16th call for projects from the French government's Fonds unique interministériel (FUI) dedicated to funding projects from competitiveness clusters.

Photoluminescent signage

Reinforcing the safety of night-time movements on an industrial site without consuming electricity or emitting CO2: securing pathways, dangerous areas, evacuation routes, stairways, etc.

Nature : Solvent or aqueous phase

Support : Bitumen - Cement - Metal

Application : Spray - Brush - Roller - Aerosol can

Smart paints

Customized coting for safety risks and monitored health-materials in industry: paint that changes color according to temperature, light, shock, solvent or gas.

Nature : Solvent or aqueous phase

Support : To be defined according to the project

Application : Spray - Brush - Roller - Aerosol can

Smart inks

Customized inks for monitoring hazards in industry and workers protection: color changing ink depending on heat, light, shock, solvent or gas.

Nature : UV solvent or photocurable ink

Support : To be defined according to the project

Application : Silk-screen printing - Flexography - Pad printing

![]()

CONTACT US

We will get back to you as soon as possible..

"*" indicates required fields